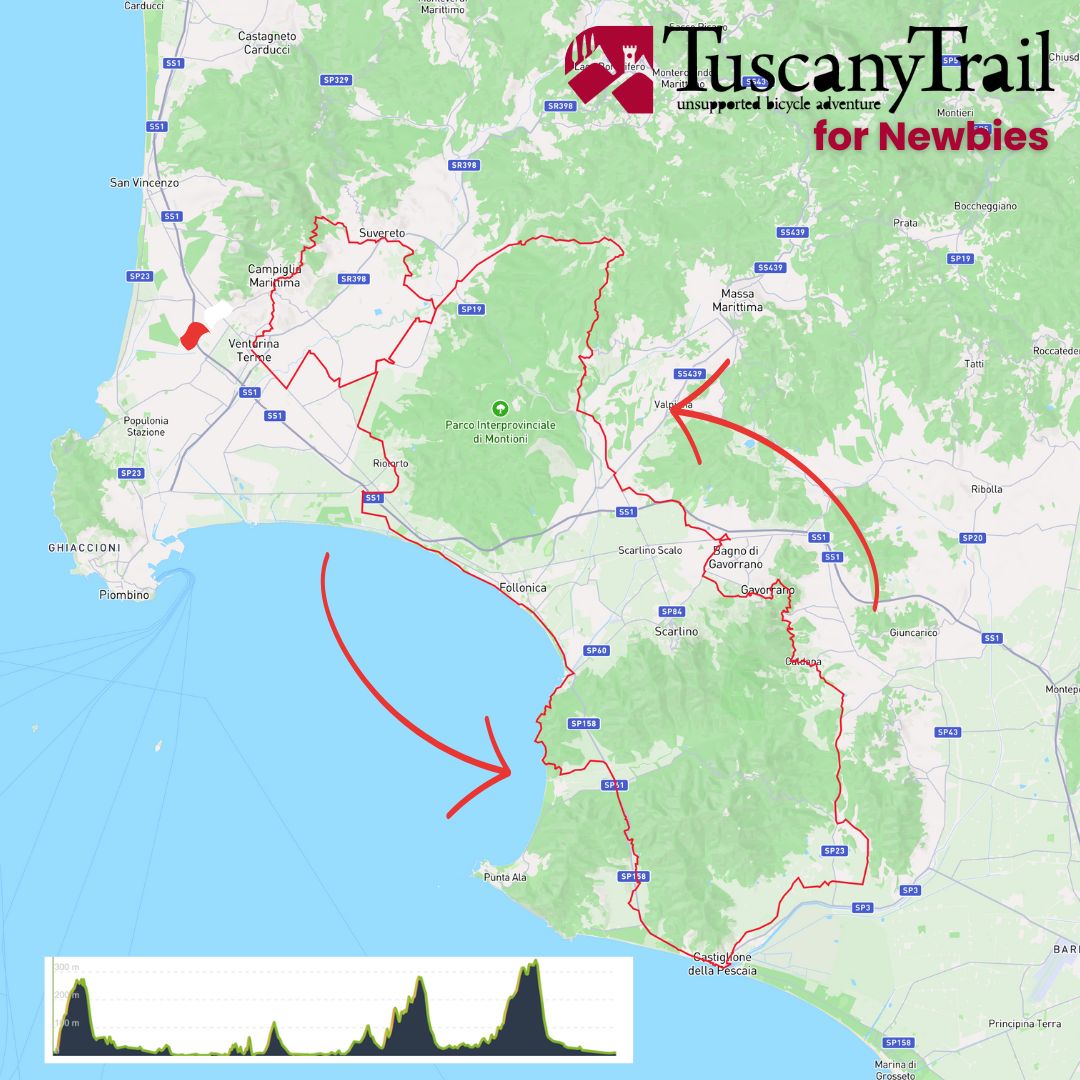

Il percorso 2025

Partecipare al Tuscany Trail vuole dire pedalare sul miglior itinerario possibile che ti farà scoprire le bellezze della Toscana. L’incessante ricerca del percorso “perfetto” è iniziata nel lontano 2007 e ad oggi non si è ancora conclusa.

L'evento è aperto a ciclisti di ogni livello, dai principianti agli esperti. La mancanza di difficoltà tecniche lungo il percorso lo rende accessibile a tutti, permettendo a ogni partecipante di vivere l'avventura al proprio ritmo, senza preoccupazioni.

Il percorso del Tuscany Trail 2025 verrà svelato solamente pochi giorni prima dell’apertura delle iscrizioni ma, come ogni anno, siamo già a lavoro per offrirvi una traccia rinnovata e autentica che sarà una gioia da pedalare sia per chi non ha mai partecipato, sia per chi è un veterano di questo evento.